Waterproof vs. Leak-Proof: What's the Difference in Toiletry Bag Construction?

Waterproof vs. Leak-Proof: What's the Difference in Toiletry Bag Construction?

You’ve packed carefully for your trip, secured every bottle cap, and nestled your toiletries into a bag marketed as “water-resistant.” Yet, upon arrival, you’re met with the all-too-familiar disaster: a foundation-smeared interior and a sticky pool of shampoo at the bottom of your suitcase. The culprit isn't just a loose cap; it's a fundamental flaw in bag construction. The terms "waterproof" and "leak-proof" are used interchangeably, but in engineering, they represent vastly different levels of protection. Understanding this distinction is the key to choosing a bag that offers true peace of mind.

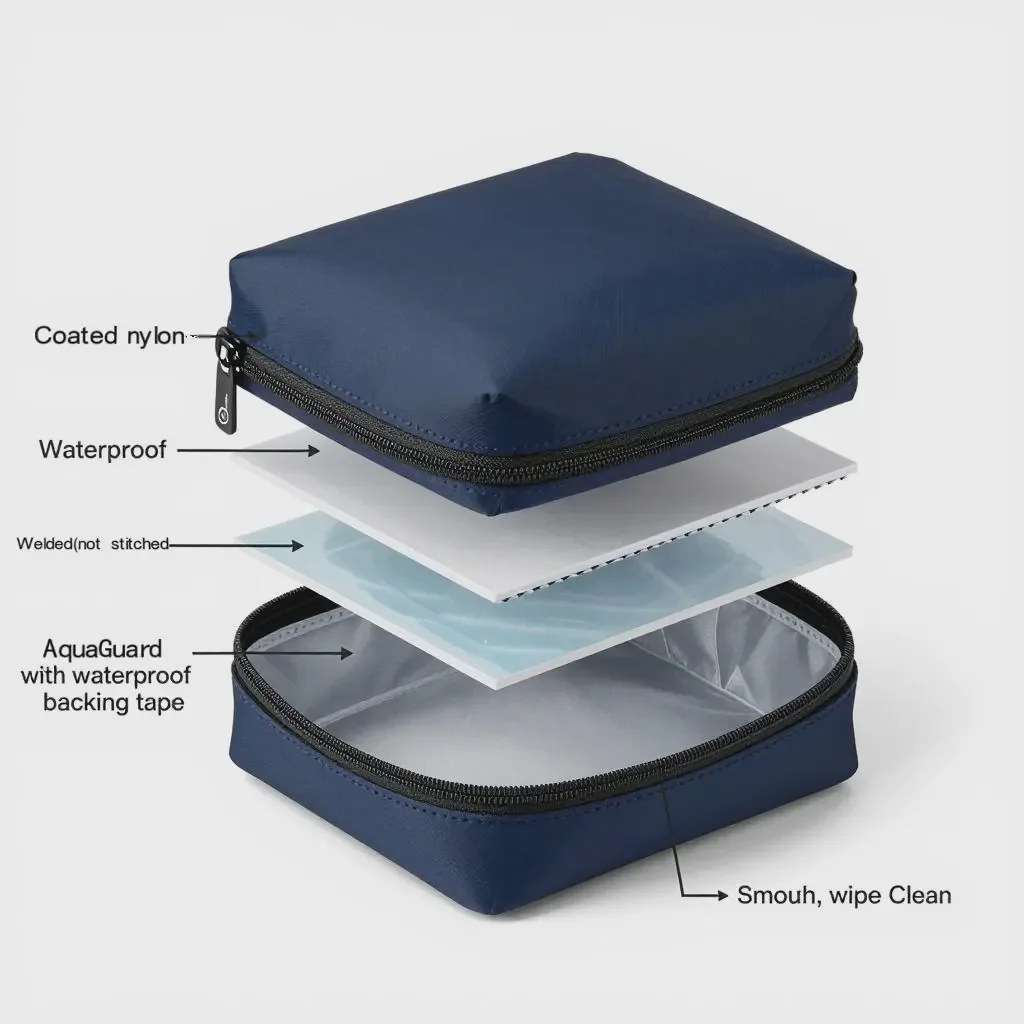

Not all protective bags are created equal. A truly leak-proof toiletry bag is a fortress built with specific, layered defenses: waterproof fabrics, fully sealed seams, specialized zippers, and chemical-resistant linings. In contrast, many "water-resistant" bags offer only a surface-level coating, leaving seams and zippers as critical failure points where leaks inevitably occur.

Choosing the right bag means looking beyond marketing claims and understanding the hidden engineering. Let's dissect the anatomy of a spill-proof bag, from the molecular bonds in its seams to the technology in its zipper teeth, so you can invest in protection that actually works.

To demystify bag construction, we will explore four pillars of spill-proof engineering: the hierarchy of protective materials, the critical battle of seam sealing, the underestimated importance of zipper technology, and the interior systems that contain disasters. Master these, and you'll never face a messy surprise again.

Material Science 101: What Makes a Fabric Truly Waterproof?

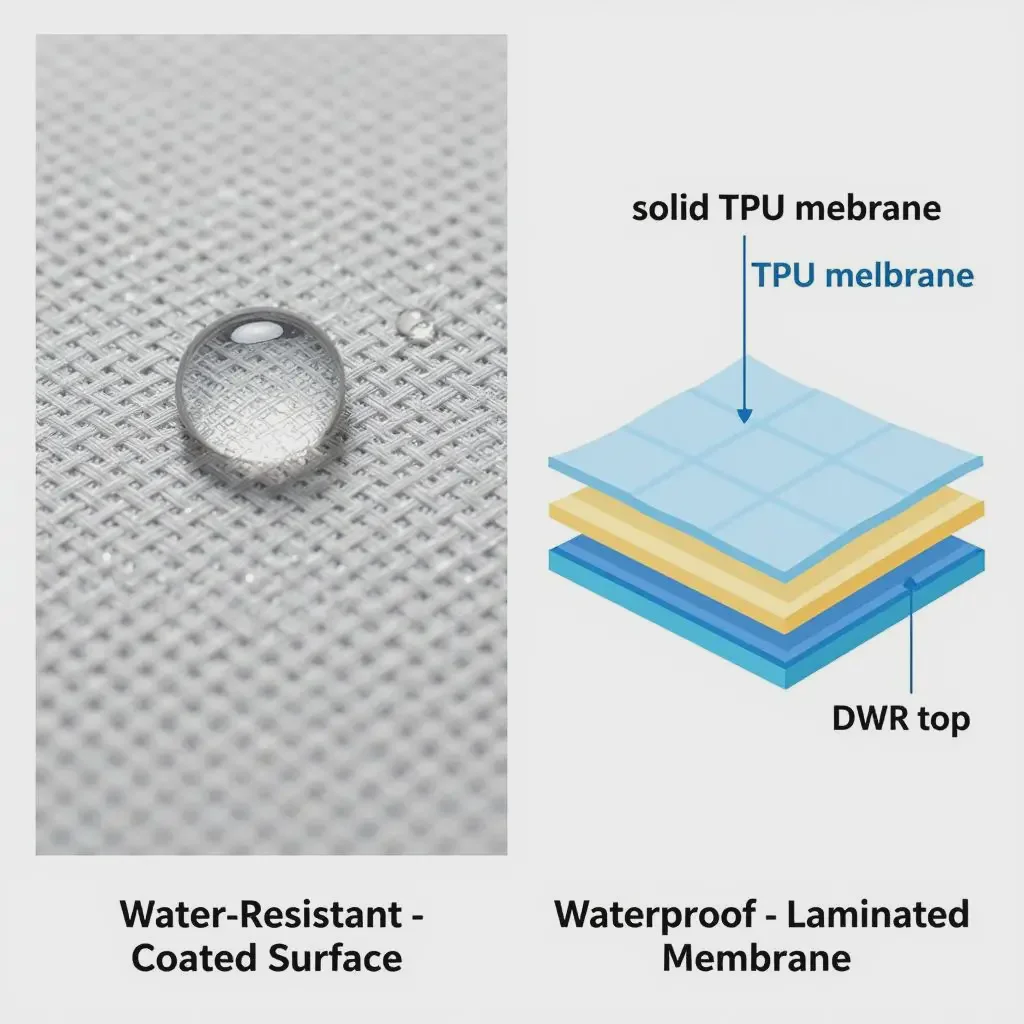

The journey to a dry bag begins with its outermost layer. The terms "water-resistant," "water-repellent," and "waterproof" describe specific scientific capabilities, not interchangeable marketing fluff. The fabric's construction and coating determine its fundamental relationship with moisture.

Water-resistant fabrics have a coating that causes water to bead up and roll off under light, brief exposure. Waterproof fabrics, however, are engineered to prevent water from passing through under sustained pressure, typically achieved through a durable water-repellent (DWR) treatment on top of a waterproof breathable membrane (like TPU) laminated to the base fabric.

For toiletry bags, the gold standard is a laminate. Here, a waterproof thermoplastic polyurethane (TPU) film is permanently bonded to a durable base fabric like nylon or polyester. This creates a monolithic barrier; there are no pores for liquid to penetrate. The TPU layer is also highly resistant to oils and chemicals found in cosmetics, preventing degradation. In contrast, a simple coating (like polyurethane sprayed onto the fabric's back) is merely water-resistant. It can crack, peel, and lose effectiveness with flexing and age. When evaluating a bag, look for specifications like "TPU laminate" or "PVC-free waterproof lining." The denier (D) of the base fabric (e.g., 600D) indicates thickness and durability, but it's the laminate that guarantees impermeability.

The Seam Wars: Are Welded, Taped, or Stitched Seams Best?

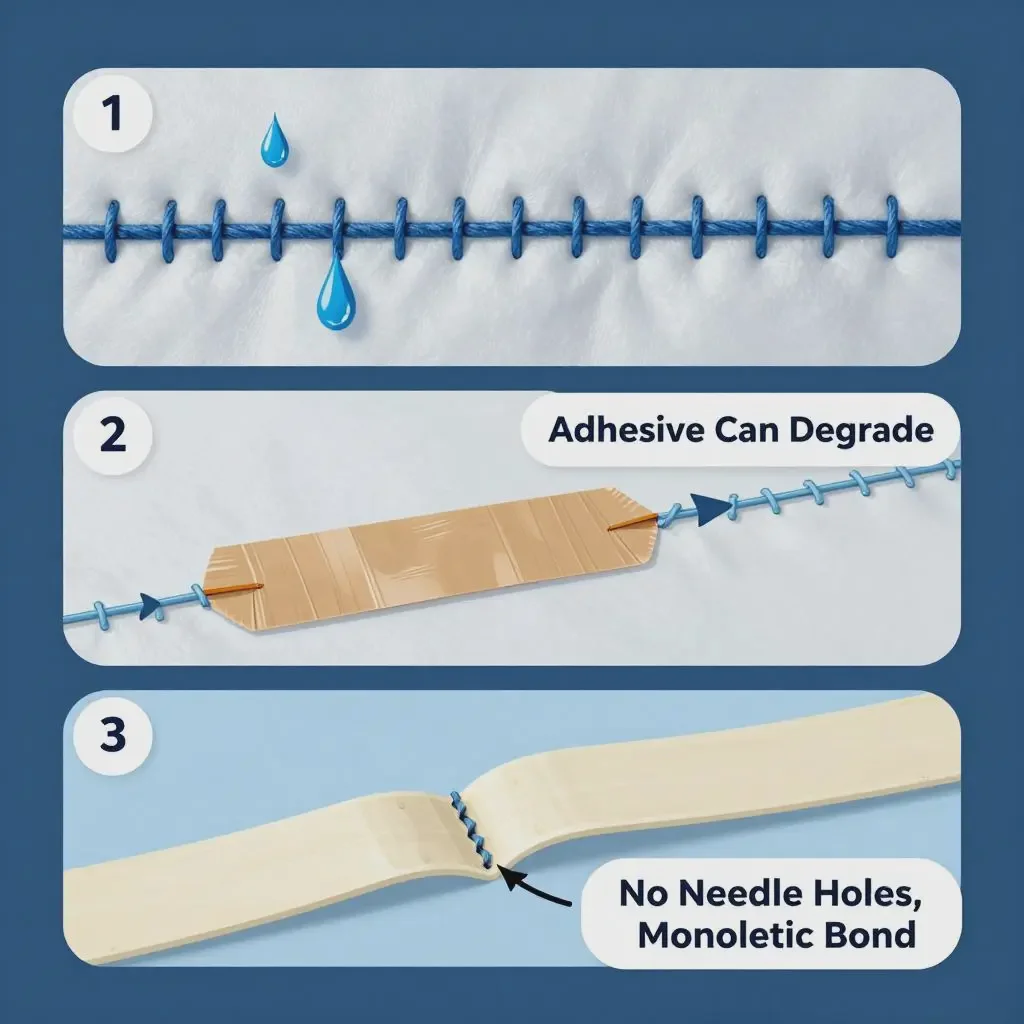

Even the world's most waterproof fabric is useless if its seams leak. The seam is the Achilles' heel of bag construction, where hundreds of tiny needle holes create a direct path for liquid. How these holes are sealed separates a truly leak-proof bag from a pretender.

Stitched seams alone are never waterproof. Taped seams cover the stitch line with a waterproof tape, a good solution for rain gear, but prone to adhesive failure in flexible bags. Welded (or heat-sealed) seams are the professional standard for absolute waterproofing, using heat and pressure to fuse material layers without any penetrating stitches.

Welding is a game-changer. It transforms multiple layers of fabric and laminate into a single, homogeneous piece at the seam. This process, often using high-frequency radio waves or ultrasonic energy, creates a bond as strong as the material itself. There are zero perforations for liquid to exploit. Taped seams, while common in mid-range bags, rely on adhesive. This adhesive can become brittle in cold, gummy in heat, or simply lose bond over time with the constant flexing of a toiletry bag. For ultimate confidence—especially if you check luggage that might sit on a tarmac in the rain or in a pressurized cargo hold—insist on welded seams. Run your finger along the interior seam; if you feel a raised, tape-like strip, it's taped. If it feels smooth and seamlessly integrated, it's likely welded.

Zipper Technology: Why Is This the Most Common Failure Point?

The zipper is the most dynamic and stressed part of any bag, and consequently, the most likely source of failure. A standard coil zipper is a clever water channel, perfectly designed to guide liquid right into your bag. Overcoming this requires specialized engineering.

Standard zippers have gaps between their coils or teeth. Water-resistant zippers add a protective flap (rain flap) on the outside, which can be bypassed by pressurized or pooled liquid. Waterproof zippers, like YKK's AquaGuard®, feature a patented waterproof polymer coating on the back of the zipper tape and a specially designed seal behind the teeth that blocks water ingress even under pressure.

The magic of a true waterproof zipper lies in its integrated sealing system. As you close the zipper, the specially shaped coils or teeth interlock in a way that minimizes gaps. More importantly, a flexible, waterproof membrane is bonded to the back of the zipper tape. When the zipper is closed, this membrane forms a continuous barrier behind the zipper path. Even if a tiny amount of water gets past the teeth, it hits this backing and cannot penetrate the fabric. Look for zippers branded as "AquaGuard," "Hydrolock," or "waterproof sealed." Also, note the zipper size (#5, #8, #10); a larger number indicates a larger, more robust zipper that will withstand frequent travel abuse better than a delicate one.

Interior Defense Systems: What Happens When a Leak Occurs Inside?

The final line of defense assumes a breach has occurred. A truly leak-proof bag is designed not only to prevent external moisture from getting in but also to contain and manage internal spills, minimizing damage and facilitating easy cleanup.

The best interior is a smooth, seamless, and chemically resistant basin. A TPU laminate lining that extends up the sides and is welded at the seams creates a "bathtub" effect, pooling any leak for easy disposal. This should be paired with a dark color to hide stains and a texture that allows for complete wipe-downs with a cloth.

Many bags fail internally by using a simple sewn-in lining fabric. Liquid soaks into this fabric, spreads via capillary action along stitch lines, and eventually wicks through to the exterior. The ideal construction is a mono-body design where the waterproof exterior material folds inward to become the interior, or where a separate TPU liner is welded (not sewn) to create a seamless reservoir. Furthermore, consider the geometry. Rounded corners are easier to wipe clean than sharp, boxy corners where gunk accumulates. For ultimate organization and secondary containment, look for removable, sealed pods or pouches within the main waterproof compartment. This creates a "double-hull" system, isolating potential leaks from your other items.

Conclusion

Achieving a truly leak-proof toiletry bag is an exercise in holistic engineering, where every component—from the molecular structure of the laminate to the sealing technology of the zipper—must work in concert. It's a system designed to defend against both the external elements and the internal hazards of travel.

By understanding the critical differences between water-resistant coatings and waterproof laminates, recognizing the superiority of welded seams over taped or stitched ones, insisting on engineered waterproof zippers, and seeking out seamless, wipe-clean interiors, you can move beyond marketing claims. You become an informed buyer who selects bags based on verifiable construction features. The goal is not just to resist a drizzle, but to confidently contain a full-bottle shampoo explosion at 30,000 feet. Your next bag shouldn't just promise protection; its very anatomy should guarantee it.