Pattern Grading and Size Range Strategy for Cosmetic Pouches: What's the Smart Approach?

Pattern Grading and Size Range Strategy for Cosmetic Pouches: What's the Smart Approach?

You've created the perfect cosmetic pouch—the ideal size, flawless proportions, and just the right amount of space for daily essentials. The samples are beautiful, and the feedback is glowing. Now comes the critical business decision: how do you transform this single successful prototype into a cohesive, market-ready collection? The answer lies not in guesswork or simple scaling, but in the deliberate science of pattern grading and strategic size planning. Done correctly, it builds a product line that feels intentionally designed; done poorly, it creates a disjointed collection that confuses customers and strains production.

Effective pattern grading is the technical process of systematically scaling a base design to create multiple sizes while preserving its aesthetic harmony and functional integrity. A smart size range strategy goes beyond mere measurements—it aligns your product offering with market demand, optimizes production efficiency, and maximizes your brand's reach without diluting its identity.

Moving from a single hero product to a full collection requires equal parts technical precision and commercial savvy. It's where design meets data, and creativity confronts logistics. Let's decode the methodology that turns a great pouch into a great product line.

To master this process, we need to understand four interconnected pillars: the fundamental principles of grading itself, the strategic decisions behind defining your size range, the practical implications for manufacturing, and the commercial strategy for bringing it all to market successfully.

Pattern Grading 101: Is It Really More Than Just Scaling?

At first glance, creating a larger or smaller version of a pouch seems straightforward—just adjust the dimensions. However, true pattern grading is a nuanced discipline that ensures every size in your range is proportionally correct, functionally sound, and recognizably part of the same family.

Simple digital scaling distorts designs. A zipper pull that's chic on a small pouch becomes awkwardly large on an extra-large version; a perfectly placed pocket becomes functionally useless when only its position is scaled. Pattern grading applies specific, rule-based increments to individual pattern pieces—width, height, gusset depth, strap length—to maintain the design's intended look and feel across all sizes.

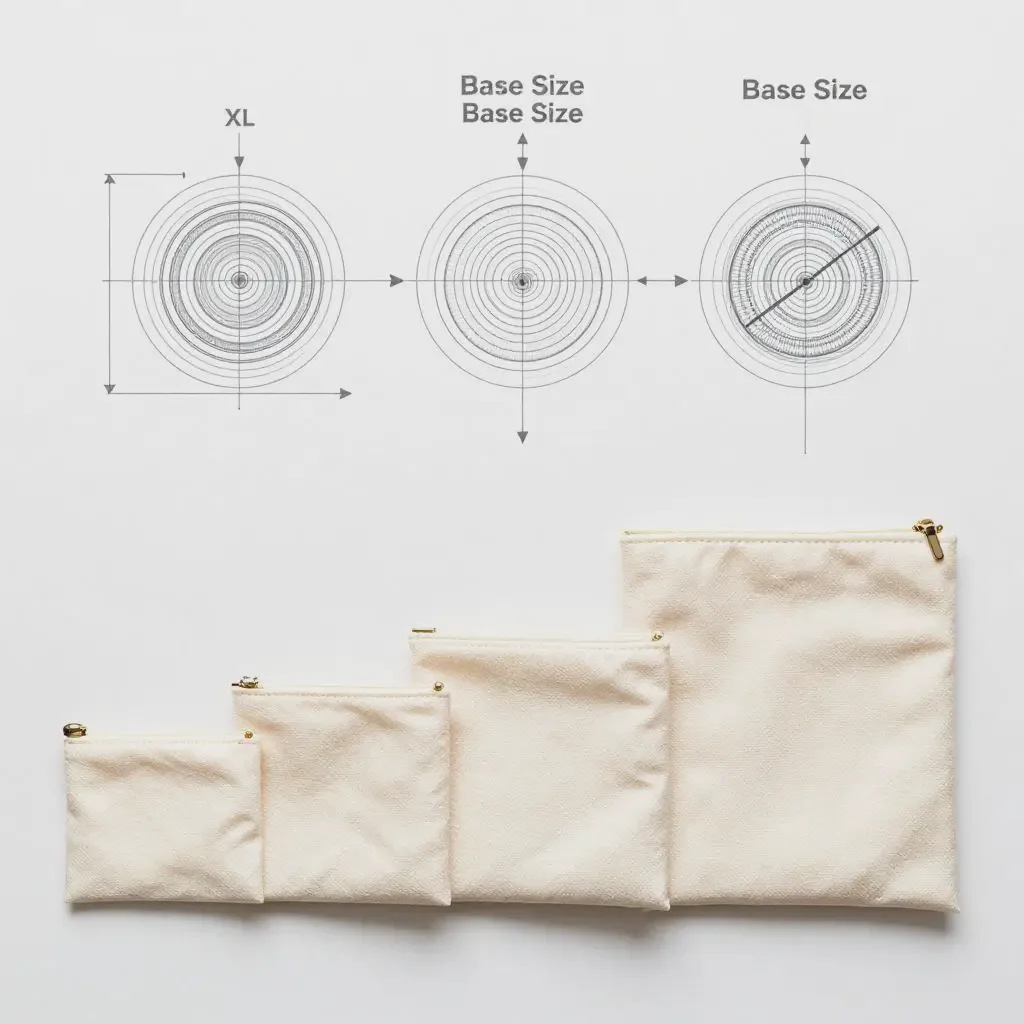

Think of it like clothing grading: you don't just make a medium shirt larger in all directions to create an XXL; you increase the chest, sleeve length, and shoulder width by different, standardized amounts. For a cosmetic pouch, key grading points include the zipper length-to-width ratio, the gusset depth relative to capacity, and the handle drop length relative to the pouch's height. A common beginner mistake is keeping the strap width the same while scaling the bag body, making the strap look and feel disproportionately skinny on a large bag. Proper grading uses a grading rule table that specifies, for example, a 2.5cm increase in width, a 2.0cm increase in height, and a 0.75cm increase in gusset depth between a Medium and a Large. This systematic approach ensures consistency and quality.

The Size Range Blueprint: How Many Sizes Are Actually Ideal?

The temptation to cater to every possible customer with countless sizes must be balanced against operational complexity and market clarity. Your size range is a strategic business tool, not just a design exercise.

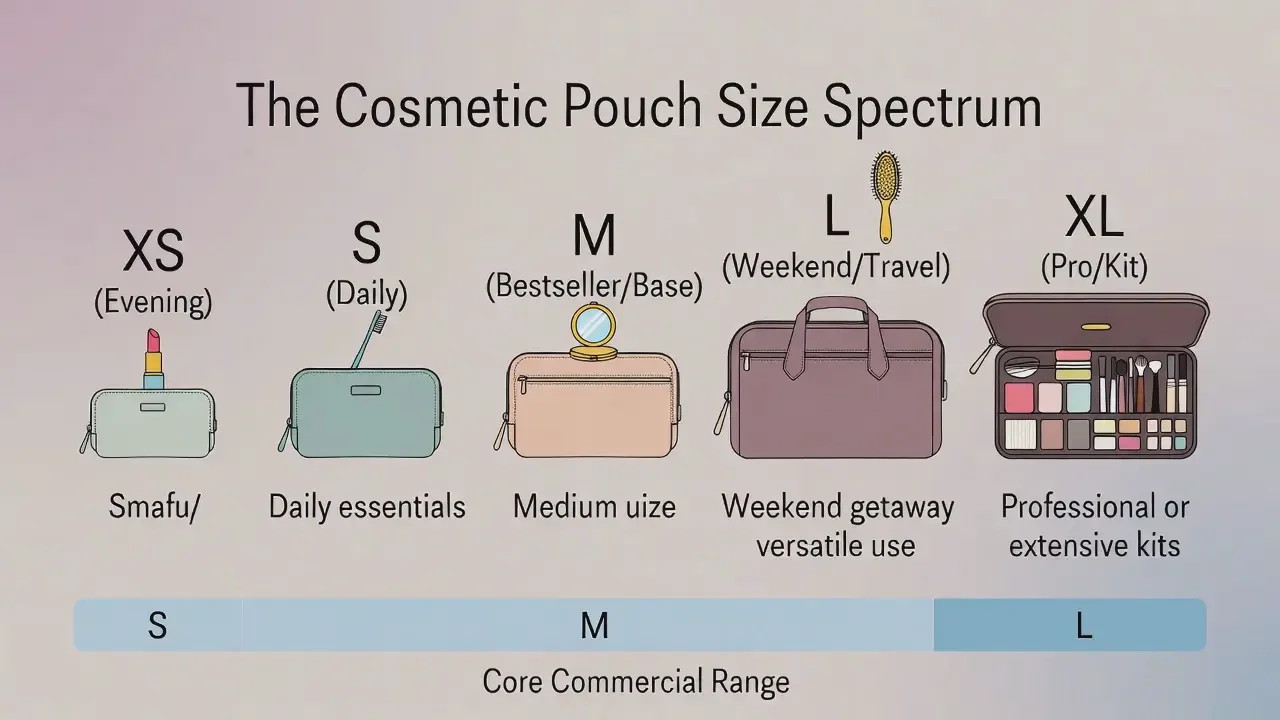

For most cosmetic pouch brands, a 3 to 5-size range hits the sweet spot between offering choice and maintaining focus. A typical, effective progression might be: XS (Mini) for lipsticks and cards, S (Small) for daily essentials, M (Medium) as the bestseller/base size, L (Large) for travel, and potentially XL (Extra-Large) for professional makeup artists or as a premium statement piece.

Choosing your base size (the pattern from which all others are graded) is a critical first decision. This should be the size you anticipate as your volume leader—often the Medium. It's the size you'll sample and photograph most, and it should represent the perfect balance of your design's features. When defining increments between sizes, consider both psychology and practicality. The jump from Small to Medium should feel meaningfully different to the customer (holding several additional items), not just a minor centimeter change. Furthermore, align your sizing with common product dimensions. For example, ensure your Large can comfortably fit a standard travel-sized toothpaste tube (approx. 19cm) and your Small can hold a popular smartphone model. This user-centric approach to sizing ensures your range meets real needs.

From Paper to Production: How Does Grading Impact Manufacturing?

A beautifully graded pattern on screen means nothing if it creates chaos on the factory floor. The transition from design to bulk production is where your grading strategy is truly tested, with direct implications for cost, quality, and timing.

Proper grading streamlines production by creating efficient marker layouts (the plans for cutting fabric) that minimize material waste across all sizes. However, it also introduces complexity: each new size requires its own set of patterns, possibly adjusted hardware (zippers of different lengths), and careful production planning to ensure workers can efficiently switch between sizes without errors.

[sub-heading 3 featured image: A visual of two fabric "markers" or cutting layouts. One is messy with poor nesting of different-sized pattern pieces, showing large wasted fabric areas. The other shows a well-graded set of patterns (S, M, L) nested together tightly like a puzzle, dramatically reducing waste. Text highlights "Material Yield Optimization."]

The financial logic is clear: optimized material usage directly increases your gross margin. A well-planned size range allows factories to "nest" pattern pieces of different sizes together on a roll of fabric or leather, using nearly every inch. Furthermore, consider hardware standardization. Can you use the same zipper slider for 2-3 sizes, only changing the tape length? Can the same magnetic snap work across the range? Forcing factories to source custom, unique hardware for every single size skyrockets costs and lead times. The most successful grading strategies are developed in consultation with your production partner. They can advise on practical increments that align with their cutting machines, their workers' ergonomics, and their access to standard component sizes. Always, always produce physical sewn samples (not just mock-ups) of every graded size to test construction, proportion, and function before cutting bulk material.

The Market Strategy: How Should You Price and Position Different Sizes?

Your size range is a portfolio, and each size should play a distinct role in your overall business strategy. Pricing, marketing, and inventory planning must be tailored to turn your technical grading work into commercial success.

Implement tiered pricing with strategic gaps. The price increase from one size to the next should reflect the actual cost increase (materials, slightly more labor) plus a perceived value increment. Your Medium size should be positioned as the "best value" to drive volume, while your Small can be an entry-point gift item and your Large a premium "solution" for specific needs like travel.

Psychology is key. Avoid pricing that is simply proportional to size (e.g., if Small is $10, Medium is not necessarily $15). Instead, use pricing to guide customers. A classic structure might be: XS: $12, S: $18, M: $22, L: $28, XL: $38. The jump from M to L is larger, justifying the significant capacity increase for travel. Your marketing should tell a story for each size. Don't just list dimensions—show them in use. Photograph the XS in a clutch at a wedding, the S in a handbag for a day out, the M on a vanity, the L packed in a suitcase, and the XL open with a full makeup kit inside. This lifestyle marketing helps customers self-select into the right size. Finally, plan your inventory and SKU management accordingly. You will likely sell 60-70% of your volume in just 2 core sizes (often S and M). Forecast and produce accordingly to avoid being stuck with dead stock in your extreme sizes while missing sales on your core.

Conclusion

Developing a strategic size range through meticulous pattern grading is one of the most impactful ways a cosmetic pouch brand can demonstrate professionalism, understand its customer, and build a sustainable business. It transforms a single product into a scalable system.

Mastering pattern grading means respecting the geometry of your design while applying commercial intelligence. It's the bridge between a designer's vision and a factory's capabilities, between a customer's desire for choice and a brand's need for focus. By grounding your size strategy in the technical discipline of grading, aligning it with tangible user needs, planning for production efficiency, and supporting it with smart commercial tactics, you build more than a line of pouches—you build a coherent brand world where every product has a purpose and a place. Start with a flawless base pattern, grade it with intention, and bring it to market with strategy.