MOQ, Lead Time, and Cost: Can You Master the Trifecta of Cosmetic Bag Material Purchasing?

MOQ, Lead Time, and Cost: Can You Master the Trifecta of Cosmetic Bag Material Purchasing?

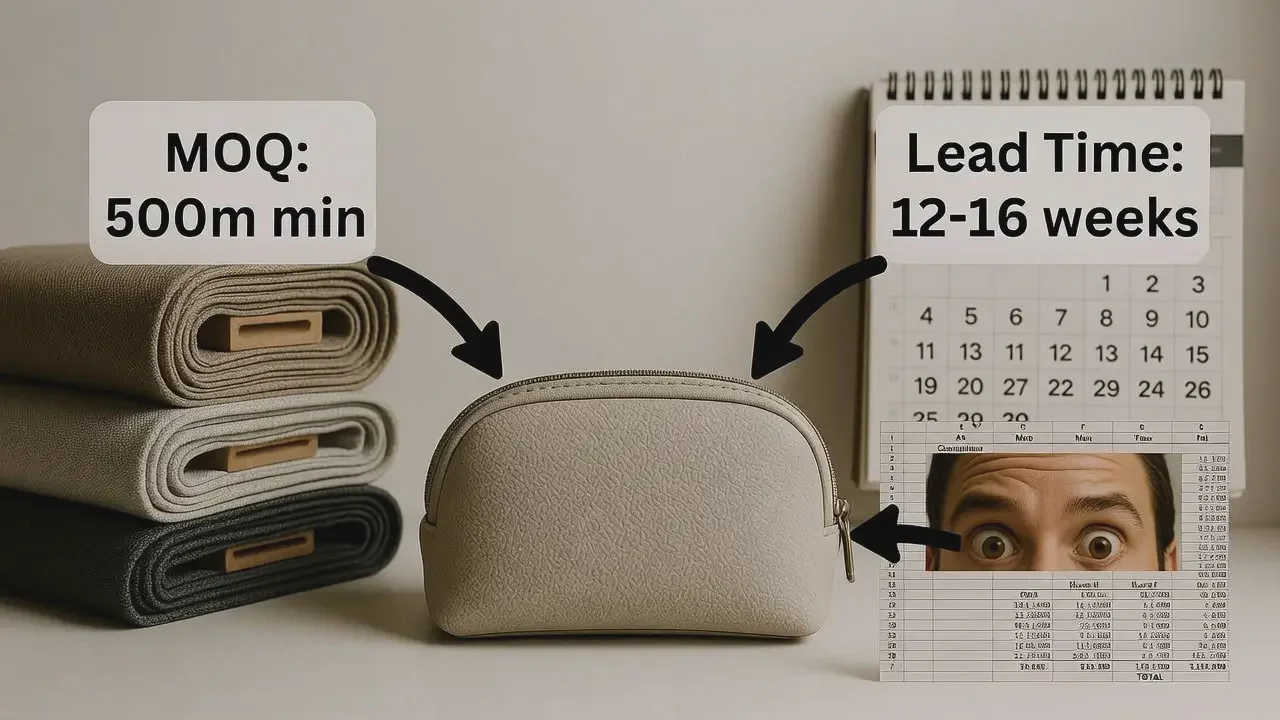

Launching a cosmetic bag line is an exercise in careful balance, and nowhere is this more apparent than in the critical phase of material purchasing. You're caught between the factory's Minimum Order Quantity (MOQ) demands, the unforgiving calendar of lead times, and the relentless pressure of your cost spreadsheet. Order too little, and you can't start production. Order too much, and you're stuck with dead inventory. Misjudge the timeline, and your launch misses the crucial holiday season. Underestimate costs, and your margins vanish. This isn't just shopping; it's strategic resource management that determines whether your brand thrives or merely survives.

Successfully navigating cosmetic bag material purchasing requires treating MOQ, lead time, and cost not as isolated obstacles but as interconnected variables in a single equation. The goal is to find your brand's unique equilibrium point—the order quantity that satisfies supplier requirements without overburdening cash flow, delivered on a timeline that aligns with production and sales cycles, at a total cost that preserves healthy margins.

To move from feeling overwhelmed to being in control, we need to dissect each element, understand its relationships, and develop a proactive planning framework. Let's transform this daunting trifecta into a manageable strategy.

We'll break down this complex challenge by first demystifying what MOQ truly represents for your business, then mapping the often-overlooked journey of materials through the supply chain, followed by a full audit of all costs beyond the unit price, and finally, synthesizing this knowledge into a practical, risk-aware purchasing plan.

MOQ Unpacked: Is It Just a Number or a Strategic Lever?

Minimum Order Quantity often feels like an arbitrary barrier erected by suppliers. However, understanding the "why" behind the MOQ is the first step in transforming it from a constraint into a tool you can strategically negotiate and leverage for better terms.

An MOQ represents the minimum volume at which a supplier's production becomes economically viable, covering their fixed setup costs and achieving efficient machine run times. For you, the brand, it's not just a purchase threshold—it's a key variable that directly impacts your per-unit cost, cash flow commitment, and inventory risk. The goal is to find the optimal order size that respects the supplier's economics while aligning with your sales velocity and financial capacity.

Negotiation is rarely about simply asking for a lower number. It's about creating value for the supplier in other ways. Consider these levers: 1) Price Premium: Offer to pay 10-15% more per unit for a 30-40% lower MOQ. 2) Consolidated SKUs: Combine multiple colorways or similar styles into one total order that meets the MOQ. 3) Forecast Commitment: Provide a credible 12-month rolling forecast and commit to a longer-term contract, giving the supplier confidence in future business. 4) Material Standardization: Use the supplier's stock materials or colors instead of demanding custom options that require separate, smaller production runs. Smart brands treat MOQ discussions as partnership-building conversations, not adversarial haggling.

The Lead Time Labyrinth: Where Do the Weeks Actually Go?

"12-16 weeks" is a common lead time quote, but without understanding what fills those weeks, you're planning in the dark. Lead time is not a single block but a sequence of interdependent events, each with its own potential for delay.

Total material lead time is the sum of sourcing time (finding and approving suppliers), production time (the supplier making your fabric, zippers, etc.), shipping and logistics time (often the most volatile phase), and receiving and inspection time at your factory. A delay in any one stage cascades through the entire schedule, pushing back your production start date and, ultimately, your product launch.

[sub-heading 2 featured image: A Gantt-chart style timeline titled "The 16-Week Material Journey." Horizontal bars represent: Week 1-2: "Supplier Sourcing & Sampling," Week 3-8: "Material Production (longest for custom fabrics)," Week 9-11: "Ocean/Air Freight + Customs Clearance," Week 12: "Warehouse Receiving & QC Inspection." Red warning icons hover over "Customs" and "QC," indicating common delay points. A dotted "Buffer" bar extends the timeline.]

To manage this labyrinth, you must work backward from your production start date. Identify your critical path item—the material with the longest lead time (often a custom-dyed or printed fabric). Place that order first. For example: If your production starts October 1st, and custom fabric takes 10 weeks, it must be ordered by July 15th. Standard items like common zipper colors (4-week lead time) can be ordered in early September. Use a shared digital calendar or project management tool to visualize all material timelines together. Always build in a buffer of 10-15% of the total quoted lead time for unexpected events like port congestion, documentation errors, or quality rejections during inspection. The most common mistake is assuming all timelines are fixed; prudent planning assumes some will slip.

The True Cost Equation: What's Hiding Beyond the Unit Price?

The price per meter of fabric or per hundred zippers is merely the headline figure. The true cost of landed materials includes a cascade of additional expenses that, if overlooked, can silently erode 20-30% of your projected margin.

Your total landed material cost must account for direct costs (the unit price), logistics costs (shipping, insurance, duties), transaction costs (bank fees, currency conversion), quality assurance costs (inspections, testing), and holding costs (warehousing, insurance, capital tied up). Failing to budget for this full picture is the fastest route to a financial surprise.

[sub-heading 3 featured image: A pie chart titled "The Full Cost of Landed Materials." Slices: 55% "Unit Material Cost," 20% "Freight, Duties & Insurance," 10% "Tooling & Setup Amortization," 8% "Quality Control & Testing," 5% "Warehousing & Financing," 2% "Payment & Transaction Fees." An arrow points from the chart to a shocked emoji, highlighting how the extra 45% beyond unit cost is often overlooked.]

Build a comprehensive costing model. For a shipment of fabric from Asia to the US, add: Ocean Freight (~$2,000-$4,000 per container, prorated), Import Duty (specific HTS code for your material, e.g., 17% for synthetic fabrics), Customs Broker Fees ($200-$500), Port & Trucking Fees (~$500-$1,000), and Material Testing (~$400-$800 for compliance). Also, factor in the cost of capital: money tied up in inventory for 3-4 months isn't available for marketing or other operations. A sophisticated approach calculates the Economic Order Quantity (EOQ), which finds the order volume that minimizes the sum of your ordering costs and holding costs. Understanding true cost empowers you to make smarter trade-offs, like accepting a slightly higher unit price from a local supplier to save on massive freight and duty expenses.

The Strategic Synthesis: How Do You Build a Risk-Aware Purchasing Plan?

With clarity on MOQ drivers, lead time components, and true costs, you can now synthesize this knowledge into a dynamic, risk-aware purchasing plan. This plan is not a one-time order but a living document that guides your procurement decisions.

An effective plan starts with accurate demand forecasting, uses that forecast to calculate optimal order quantities (balancing MOQ requirements against sales velocity), creates a synchronized material arrival schedule, and incorporates contingency strategies for every identified risk, from supplier delays to demand spikes.

[sub-heading 4 featured image: A one-page dashboard titled "Material Purchasing Plan Dashboard." It has four quadrants: 1) "Demand Forecast" (chart with conservative, expected, and optimistic scenarios), 2) "Order Schedule" (a timeline with orders for Fabric, Zippers, Hardware placed at different points), 3) "Risk Matrix" (a grid rating "Supplier Delay," "Quality Fail," "Demand Spike" by Likelihood and Impact), 4) "Cash Flow Projection" (showing outflow for material payments and inflow from sales).]

Implement this process:

Forecast with Scenarios: Create a base forecast, then a conservative (-20%) and optimistic (+30%) scenario. Plan your initial material purchase against the conservative forecast plus the MOQ.

Stage Your Orders: Don't order everything for your entire year's forecast at once. Use a phased ordering approach. Order materials for your MOQ and 3-4 months of sales. Use the sales data from that period to inform a more accurate reorder.

Dual-Source Critical Items: For your main fabric, qualify two suppliers. You may pay a small premium to the secondary source, but this insurance is cheaper than a complete production shutdown.

Define Clear KPIs: Measure Purchase Order Accuracy (materials arriving as specified), On-Time Delivery Rate, and Total Landed Cost vs. Budget. Review these metrics quarterly to refine your plan.

This strategic approach transforms purchasing from a reactive, stressful task into a core competency that provides your brand with a reliable, cost-effective supply chain—a genuine competitive advantage.

Conclusion

Mastering the interplay of MOQ, lead time, and cost in cosmetic bag material purchasing is what separates hobbyists from professional brand builders. It requires moving from seeing these factors as external impositions to understanding them as manageable components of your operational system.

By deconstructing MOQ to find negotiation leverage, mapping the lead time labyrinth to build realistic schedules, auditing all costs to protect your margins, and synthesizing this intelligence into a dynamic, risk-aware purchasing plan, you gain control. This discipline ensures your creative vision is supported by a robust and economical supply chain. It turns the critical path of material procurement from a source of anxiety into a foundation of stability, allowing you to focus on designing great products and building your brand. In the end, smart purchasing isn't about buying things—it's about buying time, flexibility, and peace of mind